E-Bike Musings

I’ve been exploring e-bikes a bit lately. I’ve been looking at the technology and some of the systems that are available to me as a small manufacturer. I’ve also dipped into some forums, started some chats and participated in some conversations. I find the attitude towards e-bikes really perplexing, and I wanted to try and get a better idea of what people (not just cyclists) feel about e-bikes and why they (e-bikes, not people) appear to be so divisive. I’m not sure that I’m really any more enlightened than I was before though! The fact that writing a piece about e-bikes is even something worth doing or has any merit puzzles me. What is it about e-bikes that makes people want to have an opinion, specifically an opinion on something that doesn’t have to impact or affect them in any way at all?

I think it’s pretty safe to say that there are a lot of people out there who think e-bikes are a bad thing. I suspect that a majority of those people consider themselves ‘real’ cyclists and have come to the conclusion that e-bikes aren’t real bikes, and somehow these new contraptions are a threat to traditional cycling. It seems to me that these anti-fans have a loud voice which exaggerates the ill-feeling and negative sentiment. The sort of comments I’ve seen over the past few weeks when digging deeper into this include statements like: ‘e-bikes are cheating’, ‘they give real cyclists a bad name’, ‘they ruin MTB trails’, they’re dangerous’, ’they’re too expensive’.

The ‘cheating’ thing, I find interesting. I’d asked on a forum what would need to happen to convince someone that an e-bike might be useful for them if they previously held a negative attitude towards them. One commentator said something along the lines of: ‘I commute to work on a regular bike and have a really steep hill at the end of the ride, an e-bike would really help at this point, but it would feel like cheating.’ Cheating who? I don’t think I really understand this. I get the fact that for a lot of people, riding their bike is often a way to push themselves physically, to get stronger, to get fitter. But if you’re just commuting to work, is it cheating? And who are you cheating? I can’t think of many other daily things we participate in where we’d rather have a harder, less efficient (yes, I know that’s going to be controversial) way of completing a task. Manual washing machines, because ones with a motor are too easy and would be considered cheating? I don’t think so. But bikes seem to elicit totally different attitudes in this respect.

Through all the conversations I’ve had, it’s become apparent that much of the negativity stems from the concept that it’s an either-or situation. You’re either an e-bike rider or a regular bike rider. The notion that it also seems to be a one-way street is prevalent. Lots of people saying things like they’re not ready to give up on regular cycling yet to get an e-bike. Like there’s some sort of natural progression from riding a regular bike to having to give that up for an e-bike. Riding an e-bike is ‘giving up’ somehow. It’s an odd situation, and I don’t really know where that comes from. Perhaps it feels like there needs to be an admission of weakness to embrace e-bikes, and many of us are not ready for this yet?

Perhaps if we spend more time talking about e-bikes as an addition to regular riding rather than a replacement, we might look on them more favourably. From a personal point of view, I’m not sure that I would choose an e-bike to ride as a regular recreational activity. I’m fit enough to ride a regular bike, and I don’t often ride with others, so not being able to keep up is never a concern for me. When it comes to riding bikes for riding bikes’ sake, I don’t think an e-bike would work for me. But there are a number of situations where an e-bike would make sense to me. I live at the top of a hill out in the countryside, and riding a regular bike to get my food shopping doesn’t appeal. It would be about an 8-mile round trip, which isn’t a lot, but loading up my bike with bags of food and slogging 4 miles back up the hill in the rain (I live in Scotland, so it will be raining) isn’t something that appeals to me. I do think that if I had an e-bike capable of carrying small to medium-sized loads, then I would probably replace a number of car journeys with bike journeys. And that’s kinda my point, having an e-bike wouldn’t really change my regular cycling at all, it would get me out of the car more and on a bike more, so that’s got to be a good thing, no?

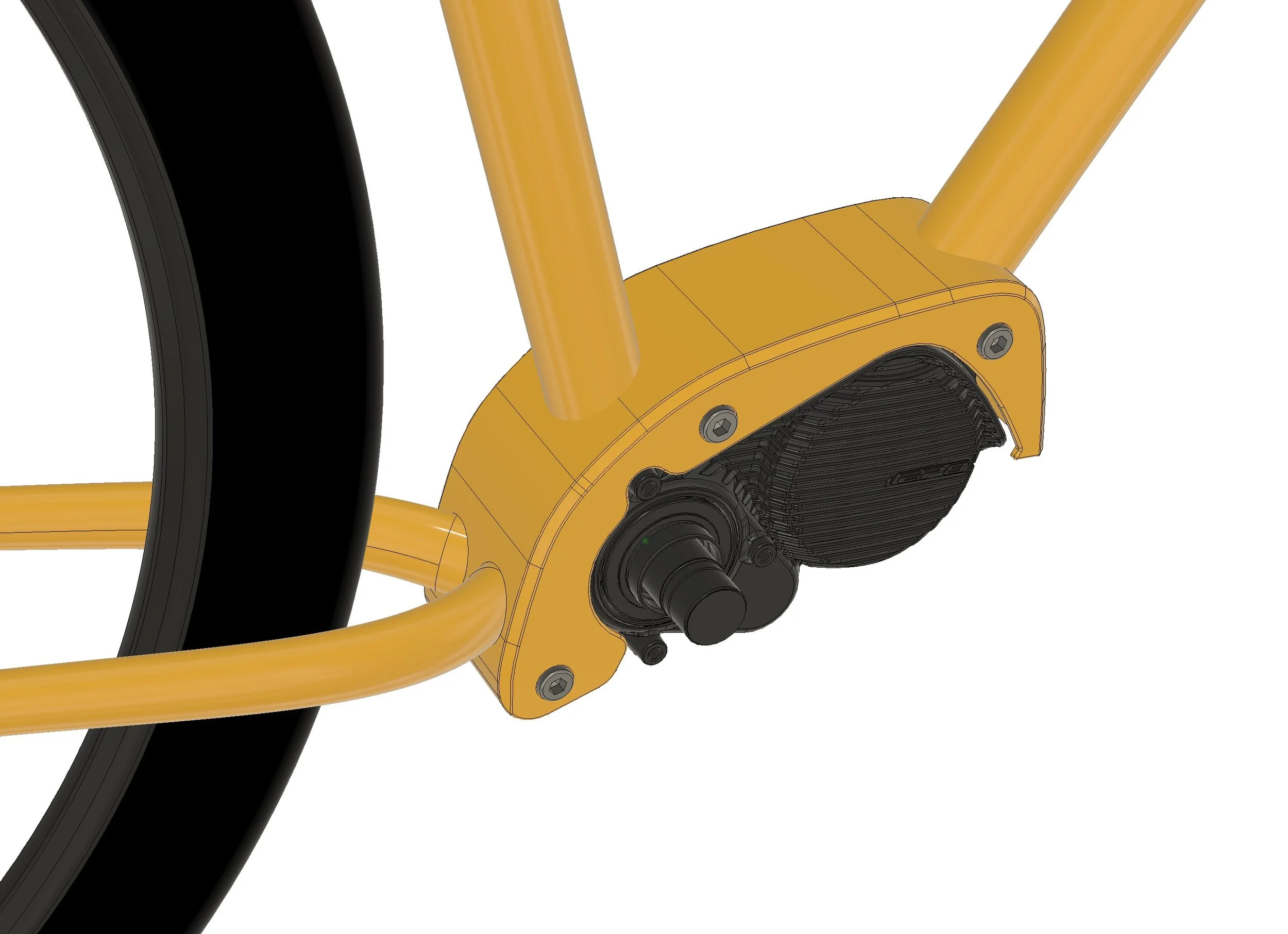

The upshot of all this is that to start 2026, I’m going to add an e-bike to the models I currently build. I’ll be keeping things simple to begin with. It’ll be pretty burly, big comfy tyres, flat bars. Shimano motor system. External battery for ease of charging, security and storage. I won’t be straying too far from my favourite transmission system, so it’ll be a Rohloff/Beltdrive bike (with a regular derailleur option). Load carrying capability front and rear with regular pannier racks. I’m not new to building e-bikes, I do a lot of design and prototype work for other brands, so I already have a good idea of what I like and don’t like and what works and what doesn’t. I’m sure this project will evolve though, so if you have any ideas, suggestions or comments, please let me know.

Everything I love about Rohloff hubs (and a couple of things I dont).

I’m going to try and explain my thinking and hopefully give you some insights into why I like to spec my bikes with Rohloff hubs whenever I can. If you have specific questions, please get in touch, and I’ll do my best to help you out. I’ll start with a list of pros and cons and go into each one in a bit more detail. I don’t pretend that the Rohloff system is without issues, and I’ll explain what I think these are. But again, I’d still choose the Rohloff system almost every time.

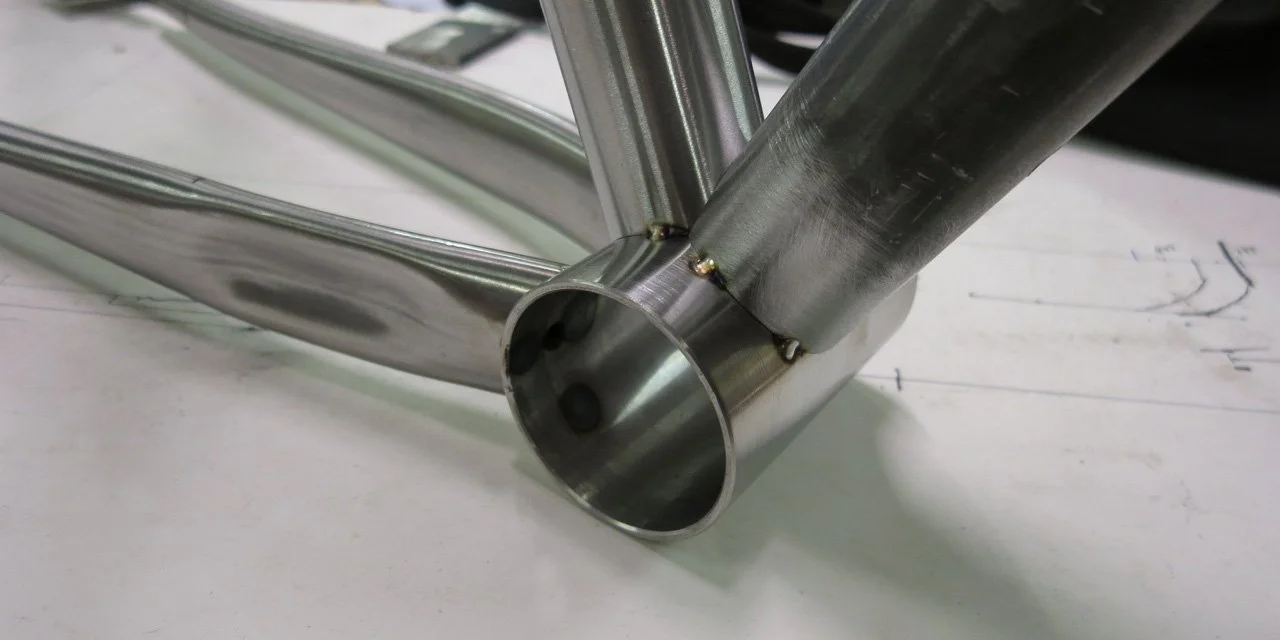

I think I built my first Rohloff bike more than 20 years ago. Since then, as I’m doing now with Willow Bike and previously with Shand Cycles, I’ve built hundreds and hundreds of bikes with the Rohloff internal gear hub. I would guess at least 95% of those bikes were also kitted out with Gates drive belts instead of chains. From that first bike I built and rode, I was sold. I knew that derailleur bikes with chains would now always seem a little clunky and inefficient. High-end transmissions from SRAM and Shimano, including electronic shifting, have continued to get better and better, but I’d still choose a Rohloff system with a belt over a traditional derailleur system almost every time.

I’m going to try and explain my thinking and hopefully give you some insights into why I like to spec my bikes with Rohloff hubs whenever I can. If you have specific questions, please get in touch, and I’ll do my best to help you out. I’ll start with a list of pros and cons and go into each one in a bit more detail. I don’t pretend that the Rohloff system is without issues, and I’ll explain what I think these are. But again, I’d still choose the Rohloff system almost every time.

Pros

Incredibly reliable

Almost maintenance-free

Predictable, consistent shifting

Shifting while stationary

Better Wheels

Cons

Cost

Weight

Availability of spares

Limited choice of shifters

Pros

1) Reliability. This one really is undeniable, and it’s a game-changer. The Rohloff Speedhub works. It works all the time. Every day, all day. It doesn’t matter what the conditions are, how old it is, or what bike it’s on. The Rohloff will just keep on working. Out of the hundreds of Rohloff hubs I’ve supplied over the years, I can honestly only remember one hub ever having to go to Rohloff to get looked at. I’m not silly enough to suggest that Rohloff hubs don’t, from time to time, go wrong for some people; they make around 35,000 hubs per year I think, so I would think a few end up with some sort of problem. But I would suggest that it’s negligible. The thing that you start to take for granted is that it’s consistent and it doesn’t wear and need adjusting in the same way a derailleur does. The indexing is all in the hub, so even if the cables stretch a little, it still doesn’t affect the indexed shifting. If you use a regular chain, that will stretch and need replacing at some point, but if you use a belt, you can expect to get close to 5 times as long before needing to make a change. The real benefit there is that as the belt wears, the performance doesn’t deteriorate in the same way a chain does. It just needs to be replaced in the same way a timing belt in a car would. It’s better to replace before it goes wrong than wait until it might fail. The service life of a Gates belt is around 30,000 km.

2) Maintenance. Or the lack of. There really isn’t much that you need to do to keep a Rohloff hub well-maintained. In fact, if you like to tinker with your bike, you might be a little disappointed by the Speedhub, as there really isn’t anything you can do. It’s pretty much a sealed unit, and there's nothing to fiddle with. The gears inside the hub run in an oil bath, and Rohloff suggests you flush out this oil and replace it either every year or every 5,000km. An oil change kit contains a lighter-weight ‘flushing’ oil, a syringe and the replacement oil. You simply remove a drain plug screw to let the old oil drain out, add the flushing oil and ride around the block shifting gears to clean and loosen up the oil in the hub before draining and filling again with the main oil. That’s it, it’ll take 10 minutes at most. The Rohloff Speedhub is operated by a couple of cables, and it’s a good idea to keep these running smoothly as you would with a derailleur system. There’s nothing special about these cables. But as I mentioned earlier, the indexing of the gears in the hub isn’t reliant on the correct tension of the gear cables, so although keeping the cables in good condition is good practice, it’s not as important as on a derailleur bike.

While we’re talking about cables, it’s worth mentioning that if a gear cable ever snaps, you can still shift the hub into any gear you want using an 8mm spanner. This means a broken or damaged cable won’t prevent you from getting home. Just select the gear that will work best for you and go for it.

3) Shifting Patterns. The Rohloff Speedhub has 14 gears with a 526% range. That means that the biggest gear is 5.26 times bigger than the smallest gear. To put that in perspective, a fairly standard ‘gravel’ drive-train (48/31 front, 11/34 rear) has a range of 477%. My opinion, though, is that although the wide range of gears is great, what’s better is that the jumps between the gears are consistent. I know that doesn’t sound like a big deal, but having predictable gear changing is something that you don’t know you need until you don’t have it! If I’ve been riding a Rohloff bike, then jump on a derailleur bike, I feel like for every gear shift I want to make, I need to shift at least twice to find the correct gear (especially with double or triple chainrings). Again, I know this doesn’t sound like a big deal, but it really is a great differentiator with the Rohloff hub.

4) Stationary Shifting. This one’s quite subtle, and the explanation doesn’t quite match what you actually experience when riding a Rohloff bike. There are two main things concerned with shifting that I really like that you can’t have on a derailleur bike. Firstly, you can shift when you’re not pedalling (and the bike doesn’t have to be moving), and secondly, the jumps between each gear are the same.

Shifting when you’re not pedalling or moving is something that you start to take for granted very quickly, and the inability to do this on a derailleur bike becomes frustrating equally as quickly! A couple of examples of how useful shifting without pedalling are: 1)coasting up to traffic lights in a big gear, knowing that when you come to a stop, you can just shift into a little gear before pulling away, 2)stopping/starting on a steep hill with a fully loaded touring bike and knowing you can just select the best gear. No more lifting the back wheel and pedalling with your hands! On technical off-road stuff, the ability to be able to shift up and down the gears while plucking your way through tricky terrain is just a great thing to be able to do. And when you can’t do it when you’re on a derailleur bike, you really do miss it.

5) Wheel Strength. This gets a little bit geeky, but there’s a very good argument that a Rohloff hub will build into a stronger wheel than a wheel with cassette sprockets. Because there are no sprockets, the Rohloff wheel can be built symmetrically. In a non-Rohloff wheel, the hub is offset, meaning the spokes need to be longer on one side than the other. A Rohloff wheel is symmetrical, so the spokes can be equal, the flanges of the hub (where the spokes connect to) are further apart and also taller, the spokes are shorter, all of this makes a much stronger wheel.

Cons

1) Ok, the elephant in the room. Cost. Upfront cost of the Rohloff Speedhub, if you’re just buying the hub on its own to build into a wheel, is high. I think today the RRP is somewhere around £1300. Just for the hub, shifter cables etc. 10 years ago (when the hub was a little cheaper), that cost seemed higher still, as the cost of a top-end derailleur was relatively low. Now, a high-end (XTR) Shimano rear mech is about £550, a shifter is about £185, a cassette is £400(!!!), rear hub is £265. So that’s £1400 before you start to add in cables, batteries etc. I know this is top-of-the-range electronic shifting, but I’m just making the point that things are crazy expensive these days, and the £1300 that a Rohloff drivetrain would cost isn’t insane. But the bigger point here is that the upfront cost of the Rohloff hub is pretty much a one-off cost for the rest of your cycling life! A £400 Shimano cassette is a consumable. It’s going to wear out. A Rohloff sprocket (which will also wear out) is less than £30. If you’re buying a bike that already has a Rohloff wheel, then the cost difference will be much less. I can buy hubs from Rohloff and roll them into my overall bike pricing at a competitive level. So, although I have cost as a ‘Con’ on my list, I’m really not sure in the long term that it is.

2) Weight. The weight of a Rohloff system (hub, shifter, cables etc) is a tiny bit more than 1800g. That does end up a bit heavier than most traditional derailleur systems, but not a huge amount, maybe 250g? Weight comparison is always a bit of a moving target. One bit of feedback that you do tend to see is that people seem to think that all the weight is concentrated in one place (over the rear axle) and that, for whatever reason, that’s not a great thing. I can kinda see that if you spend a lot of time with your wheels off the ground, but I suspect that for most riders, this simply isn’t an issue. I can honestly say that in 20 years of riding with Rohloff hubs, I’ve never once considered the possibility that there’s a weight penalty.

3) Spares. I’m not really too sure why I put this as a con. I was kinda struggling to add to that list! I think the downside on the spares front is just that, because the Rohloff system isn’t as widespread as derailleur systems, you’re unlikely to find spares in your local bike shop. I’m not sure how much of an issue that actually is. There are plenty of online stores that stock Rohloff parts, and your local bike shop will be able to order pretty much anything for next-day delivery. Having said all of that, I’m pretty confident that your need for spares is going to be pretty rare.

4) Shifters. The Rohloff Speedhub uses a rotary shifter to change gears. The stock shifter that comes with the Rohloff is a simple twist shifter that mounts to the bars. The gears are sequential, so you just shift from 1 to 14 in sequence. You can shift multiple gears at once. One of the best things about the Rohloff is the fact that the shifter is incredibly simple. It’s literally a rotating barrel that pulls a couple of cables. There’s nothing to go wrong, and that contributes massively to the reliability of the overall system. For flat MTB style bars or loop bars like the Jones bars or Jones clones, that simple rotary shifter works great. Things get a little trickier when it comes to drop bars. The stock rotary shifter won’t actually slide past the bends on drop bars so we need to look at an alternative solution. I use two different options for drop bars. The first one is a 3rd party shifter from Co-Motion which has been designed with a bigger inner barrel that will slide past the bends in most drop bars. It’s still a rotary shifter and works in exactly the same way as the stock shifter but is just a little bigger. The second solution is to use a split (two part) handlebar. I use the one from Van Nicholas and it works great. The bar splits in two under the stem clamp and this allows the stock Rohloff shifter to slide on. It’s a great solution. There is a third option that I don’t use very much anymore but it’s still available as a choice. It’s called the Gebla Rohbox and consists of a small ‘shiftbox’ that replaces the stock Rohloff shiftbox and pairs with a modified drop bar shifter (normally SRAM). This allows you to use the shift levers on a normal set of drop bar levers; one side moves you up a gear, and one side moves you down a gear. It’s a cool system and works well if you’re really used to drop-bar, STI style shifting and want to stick with that. My main issue with it, is that it’s introducing quite a complicated component into a system that works really well because of the simplicity. But it’s there as an option if you want it.

I’ll follow this article up with a more indepth look at the Gates CarbonDrive belt system. If you have any questions about any of this, please get in touch.

ChatGPT and the rise of the idiots.

The first thing I need to say here is that this isn’t going to be an AI or ChatGPT-bashing session. I don’t have any particular beef with AI. I do use it from time to time. I use it occasionally for text generation, mostly to generate text on something I don’t feel I have a strong opinion about (which isn’t much!). I was writing content for a page on the website that describes the UK’s Cycle to Work Scheme. Asking ChatGPT to generate a paragraph describing what C2W is, and how it benefits the consumer, gets me a bunch of words that I can do a quick edit on and boom! Job done. Move on to something more interesting. I also use it in Photoshop to edit images that don’t quite fit with what I need. The image below was originally taken in portrait format, but I needed something that was landscape. Photoshop has an excellent ‘generative fill’ feature that will fill out empty space on a canvas with context-aware imagery. If you look closely, you can probably make out some of the glitches or inconsistencies, but for this use case, it works great.

Only the bike is real, the background is totally AI generated.

There have been a couple of prompts over the past week or so to get me to write this rant. Each one was just a minor annoyance, but they started to come together in my brain and irritate me enough to get me to start writing this. The first thing is that I’m becoming more and more aware of people with little or no experience on a subject, spouting off as if they’re experts. I don’t know if this has always been the case, maybe I’m just noticing it more? Part of me is a little bit in awe of the confidence shown by someone to stick their head up and offer an opinion or advice on something they have very limited knowledge of. Most of my exposure to this is in the bike world. I’m on a few different forums, mostly framebuilding, and I like to try and offer help and advice to people new to the game or to anyone that’s looking for a pointer or two. There’s an example of this on one of the forums right now: a newish framebuilder has been tasked with doing quite a complicated repair on a frame they didn’t build. They’ve posted a couple of pictures and asked how they should proceed. A few seasoned framebuilders with many years of experience chime in, offer their viewpoint and some practical advice on how to proceed. Then, from nowhere, a user I’ve never heard of (that’s not to say I have to know everyone in order to validate their worth!) pipes up with a really stupid (but quite detailed) suggestion and caveats that with a statement along the lines of ‘I’ve never actually done anything like that but that’s what I would do’. I dig a little deeper and this forum user is very green. Seems pretty bright, and I’m guessing is young. The problem is that others who come across that particular post will have difficulty knowing what advice is coming from people with real-world experience and what advice is just plain wrong. At this point, it’s just a bunch of opinions, but nothing that sorts out the good from the crap. The bad advice is polluting the pool, but in a way that’s difficult to see.

In a previous life, I used to be a software developer, and all software developers will be aware of the Stack Overflow website. It’s a lifesaver. If you ever have a tech question, no matter how obscure, it’s likely that it will have been asked and answered on Stack Overflow. So you can look it up, get the info you need and move on. If it hasn’t been asked before, and you post the question yourself, you’ll likely have the correct answer within about a minute. But you’ll also have about 20 answers that are wrong, 20 answers to a different question you didn’t post and about 20 suggestions that you didn’t even ask the right question in the first place. But the really useful thing is that users of the site get to vote on the answers and responses that are given, and the ‘good stuff’ gets promoted to the top, and the crazy nonsense gets buried. There’s a really good algorithm in place that helps to qualify the responses. In most regular forum conversations and threads, none of that exists, and so the crazy is just mixed in with the sane, and someone stumbling across a subject has no way of grading that info for quality.

I was watching a video on YouTube, it was coverage of a bike show. The host was interviewing a few framebuilders and talking through the bikes they’d built and brought to the show. I try to be open-minded (really I do!), and I’m practising at being more tolerant, but I was staggered by the amount of absolute shite that was being delivered. Here are some examples (these might not be obviously crap if you’re not a bike geek, so just believe me);

‘So, it’s got roadbike handling but with fatbike wheels.’

‘I use steel from Italy, I feel it’s much stronger than the equivalent UK steel.’

‘It’s got a 71º headtube so it’s a very comfy ride.’

I could go on, but I don’t think I need to. It feels a little unfair to pick on these specific examples because the people are putting a lot of work into what they’re doing and what they’re presenting. It’s bikes and it’s all good really. But I feel we need to be less tolerant of the bullshit. That particular video I was watching was produced by a very knowledgeable bike guy; he’s done tons of videos, and I really like his content. Maybe he doesn't feel like it’s his job, but I wish he’d be a bit more challenging. I wish he’d push the guests to have a little more ownership of the subjects they talk about. A 71º headtube doesn’t make a bike more comfy but now there’s some published content out there that says it does. And nothing challenging it so you’d be forgiven for stumbling onto that and believing it.

But what does all this have to do with ChatGPT and AI? So the other thing that prompted this post was an interaction I had with ChatGPT earlier in the week. I posted something on Instagram, a picture of a part, and I was asking for help in learning what it was called. I had a few people message me with answers, exactly what I was looking for. But then my son (who is very into AI) piped up and said, ‘That’s exactly what ChatGPT is for.’ Why don’t you ask it? So I did. I gave ChatGPT a picture of the part, and within seconds, it came back with an answer and a very compelling description of what it was and how it was used. I was impressed. Except it was totally wrong. Well, not totally wrong, it was quite close, but wrong. If it was totally wrong, it would have been obvious and I could have spotted the mistake; it would have been better actually. But in this case, it was close, and it sort of made sense. In fact, if I hadn’t already been messaged the correct answer, I’d have gone with the ChatGPT suggestion and would have been tearing my hair out within a few minutes, I think.

To follow along with me on this rambling journey and have an idea of where I’m headed, you need to know how ChatGPT (and other AI platforms) get to be so clever. It’s a self-learning technology, it gets fed a shitload of data and then starts to recognise patterns and predict outcomes. The shitload of data it gets fed is basically the internet. All of it. You’re probably ahead of me here, but I’ll lay it out anyway. ChatGPT doesn’t know that the doofus answering a forum post without a clue in the world is talking out of their arse. It still gets sucked up and added to the data used for machine learning. Earlier on I said I used ChatGPT occasionally to generate some text for the website. There are various estimates bandied around that suggest anywhere from 40% to 60% of the content on the internet right now is generated by AI in some way or another. So it doesn’t take a genius to recognise the snake eating its tail. If these AI platforms are sucking in data that was artificially generated (with little to no fact checking, I’ll add) just to output some derivative text that itself gets hoovered up, it doesn’t take long for the ‘actual’ knowledge that exists on the internet to start to get bullied out of the way. It’s a self-perpetuating mess where unchecked and unvalidated content becomes pervasive. I think most of us are used to jumping online to check things, details that we’ve forgotten, methods of getting things done, and just assuming that what we’re reading is correct and factual. I don’t think we can do that anymore.

So what’s my point? I’m not sure, I’ve kinda forgotten at this point. Well actually, I think it’s that we should all start to be a bit more challenging with our interactions online. With so many platforms and outlets to effectively self-publish whatever’s in our heads, it’s no surprise that the quality of data and content that AI platforms are ingesting is hugely varied, and it’s probably safe to say that it’s on a downward trajectory. This post is a perfect example. There are no peer reviews, I don’t have an editor, and there’s no mechanism for criticism. I’m just expecting you all to believe me. Since this is largely an opinion piece, it’s not such a big deal. But it could be littered with made-up facts.

So the next time you’re interacting with something online and something smells fishy, call it out. Challenge it. Do your own research.

Don’t let the idiots drag you down.

Peace out. ✌️

Re-use, obsolescence and shit design.

A few days ago I went on a bit of a rant on Instagram. It was prompted by a carbon fibre frame that was dropped off with me to see if I could repair it. It was a few years old, maybe 5 years, something like that, and it had a seatpost with an odd clamp. The sort of clamp that seems to have made it’s way onto a few other carbon fibre frames. This was a Canyon but I’ve seen the same, or more accurately (and pertinently) similar, clamps on other bikes. It was a sort of clamp/wedge design that sits inside the frame, and it had cracked. The original owner had contacted Canyon to be told that they no longer ‘support’ that particular model he had, and they had no stock of the spare part he needed. When prodded, they had no suggestions for him; his bike was 5 years old and was effectively broken beyond repair. His options were to try and find someone who had a clamp he could buy, maybe from a broken frame somewhere, find a machinist who could make the part he needed, or discard the frame and get a new one. All for a simple part that holds the saddle up.

The thing is, we’ve needed clamps to hold seatposts in position for about 100 years and there’s a perfectly good solution. Admittedly, not every frame is the same size and so we need a few different diameters, but I think that up until the proliferation of carbon frames, I’d be confident that about 99% of all frames used a seatclamp that was one of three sizes (28.6mm, 31.8mm or 34.9mm). Note this is the size of the frame tube that holds the seatpost, not the size of the seatpost itself. A lot of carbon (and some aluminium) frames don’t have a round portion of a seattube on the frame that one of these clamps fit to, so they need to find an alternative. And that’s where I think the whole thing deteriorates. A designer sitting in an office working on these bikes has failed to address the issue of sustainability. How long will this bike last, and how can we make sure its useful life is as long as possible? That bike could absolutely have been designed to work with a standard seatclamp but the designer decided to roll their own solution. And this wasn’t a solution that they then advocated as an improvement and could be made available on all bikes in the future. No, this was a closed, proprietary design that would work on this frame and nothing else.

Seatclamp that’s worked for about 100 years on the right, stupid fucking design on the right.

Just a quick point here, I’m not against new design, new products or innovative solutions to solve a problem or move the landscape along as our requirements change or as new materials become available. Right now, there are 33 parts listed as seatclamp spares on the the Canyon website and none of these parts will work for the guy I mentioned at the start of this article. Is this good design? I don’t think so. I think it’s short sighted and lazy.

Selling bikes is hard, the market is hugely saturated and every brand is scraping around on the design room floor looking for some USPs that can push their bike to the top of the customer’s wish list. In retail, we used to call this ‘swing tag bullets’. As a customer, you’d go into your local bike shop and be faced by rows and rows of bikes and every bike had a swing tag dangling from the bars. These swing tags gave you a nice bulleted list of why you should buy that particular bike; “18 gears!”, “Quad Butted Tubing”, “Modern Geometry for Comfort and Control”. Mostly marketing bullshit but they had to try and make their product stand out. And I think this is the problem with a lot of modern bike design, the customer, and their riding experience is sliding down the list of priorities when designing a bike or frame and is being replaced with ‘features’, something that in past would find its way onto a swing tag and now is an H2 on a website. For example, this piece of gold : “Check out our highly-praised Canyon engineered seatposts and clamps, designed to maximize the performance and comfort of your bike.” Really? Come on, it’s a seatclamp, it doesn’t maximise the performance or comfort. It’s just made up crap, to label shitty design to make the customer think their experience will be better if they choose a bike with that kind of seatclamp.

I’m picking on seat clamps here specifically, but every bike has a few parts that either the rider will have to interact with, or is a crucial moving component that may wear out, or makes up the fit or comfort of the bike and can be changed. Saddles, bearings, chains, grips, pedals etc. These are all adjustable or moving parts and will probably, over the life of the bike need to be replaced or changed at some point. Either because they’ve broken, worn out or need to be replaced to make the bike work for an individual. So as a designer, it’s crucial that you make sure the life of the bike isn’t going to be cut short because you’ve designed proprietary parts that wear out, or break and can’t be replaced.

I get riled up by this sort of thing because the impact of the way we design and manufacture things is long-reaching. There’s the obvious side of my example which is that someone’s bought a bike for a lot of money that’s now no use to them, that makes the bike a very, very expensive purchase. Then there’s the waste of resources, in the initial manufacturing of the bike and the transportation of that bike from Asia to the UK. The environmental and financial cost of that is not insignificant. All so someone can ride that bike for 5 or 6 years. And now what happens to the bike? In this case, the frame is carbon fibre, and right now, I know of no consumer-level way of recycling things like carbon bicycle frames or parts. I’m not saying it’s impossible, I just don’t know of an accessible way of doing it. While I think that the ability to recycle the raw material is important when choosing what we’re going to manufacture things from, being able to reuse the product beyond the original owner’s use is a way more efficient way of reducing the environmental impact that producing a product has. The longer the life the product has, the better for all of us. Even better is not to buy anything new in the first place, but that’s a more complicated (as well as philosophical) point. And this is why intelligent design with recycling, reusing or re-manufacturing in mind is really, really important.

Used bicycles at the Bike Station in Glasgow

There are loads of organisations/groups/charities that will take older and unwanted bikes, give them a service, a clean, a tune-up and sell them on. This is the best form of recycling. Not grinding or melting everything down, but reusing them for their original purpose. It’s friendly to the environment and financially sensible too. But this only works if you can get parts to fit the bikes. You need to be able to replace the components that wear out or have been damaged. I hear from friends and colleagues who work on older bikes for reuse that getting hold of parts and trying to get bikes back on the road is getting harder and harder. It’s a bit of a standing joke in the bicycle industry that the ever-growing list of standards in the bicycle industry is getting out of control. We have multiple headset standards, multiple bottom bracket standards, multiple axle standards and multiple brake fitting standards. Then you have compatibility issues with the different number of gears on bikes that have changed over the years. That can be frustrating, but mostly they are ‘standards’. The specification is published somewhere and many different vendors can, and do, make parts fitting into these standards. It‘s not ideal when you have competing standards, but things do change as materials and manufacturing techniques improve, and as I said, I’m not against improvement and advancement. But when these existing standards get ignored and proprietary designs make it onto bikes where there’s a perfectly good existing standard, then that just becomes shitty design. It’s short-sighted and it’s irresponsible. If you’re making a consumer product that costs thousands of pounds and you can’t service, repair or support that product for many years after you’ve sold it, then that’s irresponsible. I want to see bikes like that Canyon with a broken seatclamp make it onto the shop floor of a second-hand bike shop.

I think the reason this stuff winds me up so much is that if you’re a rider that just wants a nice bike and you’re not into all the tech details, you’ll have no idea if the bike you’re interested in will have been designed with re-use or recycling in mind. I suppose my final point in this mini-rant is that bike companies need to do much better. It’s not enough to chase customers with ill-thought out design ‘ideas’. Bike companies should not only quit adding useless, badly designed proprietary features but they need to be telling people about the design elements they’re using to make sure their bike doesn’t end up as landfill in 5 years time.

Peace out.

32” (ISO 686) Wheels

If you pay attention to the goings-on within the bicycle industry, particularly the MTB side of things, you may have spotted some chat about a new wheel size. But before I dive into that, it might be worth just recapping where we are with bicycle wheel sizes as of right now. I’m not going to cover every single wheel size since the beginning of bicycle history, just the common sizes from the past 20-odd years, sizes you’re likely to have come across if you consider yourself a bike rider.

Let’s start with road bikes, at the beginning of my bike riding life, most road bikes had 27” wheels. This was close to the 700c size that most road bikes currently use. 27” was a popular size in the UK and the US but become pretty obsolete as the 700c designation that was common in Europe started to take over. The diameter of the 27” was actually a little bigger than 700c. There’s also a 650c size (not to be confused with 650b - see below) which is pretty rare but makes an appearance on some time-trial and tri bikes as well as race bikes for juveniles and smaller riders.

When mountain bikes got really popular in the 80s and 90s they all had 26” wheels, in the 2000s several manufacturers introduced the 29” wheel that most MTBs currently use. Interestingly the 29” wheel size is exactly the same size as the road 700c size. Fast forward a few years and we have an in-between size, 27.5” (also known as 650b). Not only is this popular in the mountain bike world, but has become pretty common on gravel bikes.

You might be a little confused at this point with the way we’re describing tyre sizes, you’ll have noticed that we’ve been mixing units and jumping around quite a bit. For tyres that are listed in inch sizes (eg 27”, 29”) these numbers refer to a very rough estimate of tyre diameter. Same with 700 or 650 except in this case it’s the tyre dimater in mm. The ‘c’ or ‘b’ suffix designates the width of the rim for that size of tyre. It’s not a number you can rely on but it is a convenient way of grouping tyres together.

Thankfully there are some standards that very accurately define tyre and wheel sizes and all current manufacturers adhere to these standards. The ISO wheel standard for bicycles describes a dimension that relates to the diameter of the rim where the bead of the tyre sits. Sometimes known as BSD (Bead Seat Diameter). An example of this would be ISO622 which is what all 700c and 29” rims/tyres fit into. Expanding on the ISO standards is the ERTRO standard. This takes the ISO dimension and adds a tyre width value. Like ISO, this is described in mm. An example of an ERTRO size would be 32-622 which is a 700c wheel with a 32mm tyre. I’ve added a chart at the bottom of this page that lists some common wheel sizes and their current standard designations. Check the sidewall of your tyre and you’ll see the ERTRO size.

So what does any of that have to do with 32” wheels? Well, the bicycle industry seems to have decided that a new bigger wheel size might be fun. And it seems like the 32” size (ISO 686) is the current favourite to make it onto production bikes. I should say here that 32” isn’t really a new size, it’s common in the unicycle world (along with 36” ISO 787). So there have always been tyres and rims available (well, about 2 tyre choices and about 1 rim!) and some small custom builders have been making use of these parts to build big-wheeled bikes for a while. There are a couple of companies specialising in building bikes for very tall people utilising 32” and 36” wheels in a small production environment but they are very much the exception.

With industry support, we’ll see more trye choices and more rim choices. This is already starting to happen. I have two different types of 32” tyres in stock right now (bicycle not unicycle), 1 type of carbon rim and 1 type of aluminium rim. I know of two rim manufacturers that have committed to stocking a 32” rim very soon. That trickle will turn into a stream very quickly.

This new wheel size is going to be interesting in a couple of different ways. The movement for this new size has been driven mostly from the mountain bike industry. Back in the 2000s we saw MTBs adopt the 29” (622) wheel size, effectively replacing the previous 26” (559) size. Proponents of this size argued that the bigger diameter meant the wheel rolled over obstacles better, smoothing out the ride and allowing faster speeds and more control. There wasn’t much argument against this, and 29ers became popular to the point where they are now pretty much standard. The downsides to a bigger wheel, a larger rotating mass, are that it’s harder to get the wheel up to speed, meaning a little slower acceleration, especially when pedalling out of corners, that sort of thing. There’s also the issue of the bigger rotating mass making it harder to change direction, kinda like a gyroscope always wanting to stay upright and stable. So quick changes of direction are harder. If the bigger wheel change (26 to 29) makes sense, then the logical argument is that a jump up in size again will have the same sort of benefits. I think this is true to some extent, the 32” wheel rolls over obstacles better and is especially beneficial on gravel bikes; the oversized wheel smooths out washboard-style gravel trails. But the downsides to the bigger wheel size will also be present and will be amplified. Getting those big wheels up to speed will take more effort, and on tight twisty trails, the bike will certainly feel harder to manoeuvre (everything else being the same). I think initially we’ll see people adopting a ‘mullet’ approach to the 32” wheel. The ‘mullet’ refers to a bike with two different wheel sizes, normally a bigger wheel in the front. The idea here is that you get the rollover benefits of the big front wheel to flatten the trail a little but you don’t have the downside of having to spin up a big wheel at the back. That approach is already popular with a lot of riders opting for a 29” front wheel and a 27.5” rear wheel. So the first way we’ll see 32” adoption is in the MTB world. The big wheel size will be chosen for performance and handling reasons.

The second way we’ll see widespread adoption of this size is to provide a better experience for big/tall riders. While it’s relatively easy to build a bike with contact points in the correct place for taller riders, the limitation of 700c (622) wheels means that often the rider feels like he’s stitting high up above the wheels, it can create an odd riding experience and there’s an argument that aesthetically it doesn’t look great. The two bikes you see below have exactly the same fit points, meaning the position the rider has on the bike is the same, from a comfort point of view there’s little difference. But it’s not difficult to see what bike looks ‘right’.

The fit and riding position of both of these bikes is identical. The bike on the left has 700c wheels, the bike on the right has 32” wheels.

I’m excited to see more components (tyres, rims) become available for 32” wheels, I think this is going to be transformative for bigger riders who have traditionally had to opt for the biggest production size available and then try to tweak it to work. We’ll be able to design bikes that have the rider sitting between the wheel rather than high up on top of the wheels.

So if you’re either an MTB or gravel rider looking to explore this new wheel size or a taller rider looking for something that fits and rides better, get in touch and we can talk about what we can do for you. If you’re a framebuilder and want to dip your toe into the water, building big-wheel bikes then I can help out with the supply of rims, tyres and spokes that I keep in stock here. Getting hold of these parts still isn’t too easy without committing to big quantities.

Rantings, mostly.

If you know me, you know that it doesn’t take much to get me rambling on and on about bikes, bike design, framebuilding, fabrication etc. In the early days of Shand Cycles, I used to write a fair amount of blog posts (remember blogs? they’re back baby!) but when the business was sold, the new owners deleted over 12 years worth of content. I thought that was dumb. I miss having a space to write down what’s going on in my head so I’m going to start a blog again. This is the first post. I have another one already lined up and ready to go. I don’t know how much, or how often I’m going to write. But this is a start. I might even see if I can rescue some of those original posts, maybe the WayBack Machine stored some stuff. I’ll look. Peace out.